Flanges Gerenal:

Flange is a method of connecting pipes, valves, pumps and other equipment to form a piping system. It also provides easy access for cleaning, inspection or modification. Flanges are usually welded or screwed.Flanged joints are made by bolting together two flanges with a gasket between them to provide a seal.

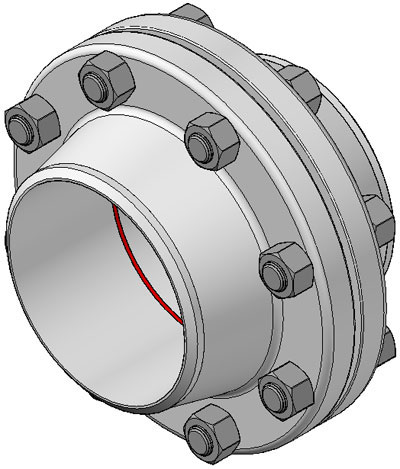

A typical flange connection:

Pipe flanges are manufactured in all the different materials. Some flanges are made of cast and ductile iron, but the most used material is forged carbon steel and have machined surfaces.

• TYPES OF FLANGES

The most used flange types in Petro and chemical industry are:

1. Welding Neck Flange

2. Slip On Flange

3. Socket Weld Flange

4. Lap Joint Flange

5. Threaded Flange

6. Blind Flange

(All types except the Lap Joint flange are provided with a raised flange face.)

Most common used flange types

— Special Flanges

Except the flanges, which are mentioned above, there are still a number of special flanges such as:

1. Orifice Flanges

2. Spectacle Blinds (part of flange connection)

3. Spades and Ring Spacers (part of flange connection)

4. Long Welding Neck Flanges

5. Weldoflange / Nipoflange

6. Expander Flange

7. Reducing Flange

• MATERIAL FOR FLANGES

The most common materials used in flanges produced is carbon steel, stainless steel, cast iron, aluminium, brass, bronze, plastic et cetera.

In addition, flanges, like fitting and pipes, for specific purposes sometimes internally equipped with layers of materials of a completely different quality as the flanges themselves, which are “lined flanges”.

The material of a flange, is basically set during the choice of the pipe, in most cases, a flange is of the same material as the pipe.

All flanges, discussed on this website fall under the ASME en ASTM standards, unless otherwise indicated.ASME B16.5 describes dimensions, dimensional tolerances et cetera and ASTM the different material qualities.

• EXAMPLE OF WELDING NECK FLANGE 6″-150#-S40

Each flange according to ASME B16.5 has a number of standard dimensions.

If a draftsman in Japan or the work preparer in Canada or a pipefitter in Australia is speaking about aWelding Neck flange 6″-150#-S40 according to ASME B16.5, then it goes over the flange which in the image here below is shown.

If the flange is ordered, the supplier want to know the material quality. For example ASTM A105 is a forged carbon steel flange, while A182 is a forged stainless steel flange.

So, in a correct order to a supplier two standards must be specified:

Welding Neck flange 6″-150#-S40-ASME B16.5 / ASTM A105

0 comments:

Post a Comment