Pipe connection is varied, the commonly used have iega profi-press, compression type and push type, welding type, and various derived connection mode.

The following table shows the different orientations of pipe connection types:

| Connection type | Connection orientation |

|---|---|

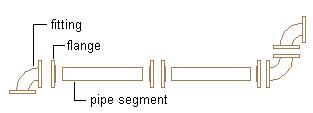

| Flanged, all types |

Fitting to pipe: Flanges are typically included on fittings. A separate flange is added to the pipe segment. Pipe to pipe: A separate flange is added to each pipe end to create the connection. Fitting to fitting: Fittings with inherent flanges connect directly to each other. No separate flanges are added to the connection. |

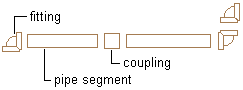

| Threaded, Socket weld, Glued, Brazed |

Fitting to pipe: Pipe segments typically have inherent male ends, and fittings are typically female. The pipe inserts directly into the fitting. Pipe to pipe: A female coupling is inserted between the pipe segments. Fitting to fitting: Fittings connect directly to each other. |

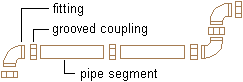

| Grooved |

Fitting to pipe: Fittings and pipe segments are considered to have grooved ends that are ready to accept a coupling. A coupling is added to connect the fitting and pipe. Pipe to pipe: A coupling is added to connect the pipe segments. Fitting to fitting: A coupling is added to connect fittings. |

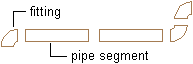

| Butt weld |

No extra objects are added. Fittings and pipe segments connect directly to each other. |

Note: The Piping domain includes a connection type called Same Connection. When Same Connection is configured for a pipe object that is attached to a hub, connector 1 inherits the connection type of the connection type on connector 2 of the attached hub. For more information, see Rules for Connector Behavior.

Remember: To build parametric fittings content, see Adding Connectors to a Parametric Fitting and Rules for Creating Parametric Fittings Content.

0 comments:

Post a Comment