A flush ring according to the chemical group’s specifications. It is mounted with a flange connection located between the primary isolation valve and the diaphragm seal. One or two ventilation and flushing connections are located on the outside of the flush ring. If the ring only has one connection, the cavity between diaphragm seal and primary isolation valve can be flushed in a controlled manner – for example, via a connected hose and a suitable collection container. The ring can, for example, be filled with compressed air or a cleaning fluid via the second connection and flushed out depending on requirements which the corresponding medium places on the system operator.

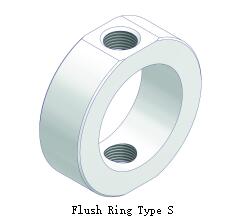

Flush Ring Type S

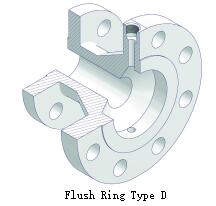

Flush Ring Type D

Standard Features

• The fushing ports allow the washing out of particles accumulated in front of the membrane.

• The pressure chamber can be vented or drained or flled with a cleaning liquid and subsequently fushed, depending on the requirement.

• Various nominal widths and forms allow adaption to the respective process fange. See Optional Features.

• Standard fushing connection: 1/2 NPT female

• Sealing face:

– Acc. to EN 1092-1 Form B1

– Acc. to ASME B 16.5 RF

• Materials: F53/316/316L/1.4401/1.4404,etc

Optional Features

• Flushing connection with different female threads: G1/2, G1/4, 1/4NPT

• Pipe plugs and various valves

• Other sealing faces, e.g. groove, tongue, RTJ

• Exotic Alloys, e.g. Duplex, Alloy C-276, Alloy 625

• Flush rings for sour gas service are available in accordance with NACE MR0175/ MR0103 and ISO 15156 by default.

• Special cleaning

• Inspection certifcate 3.1 acc. to EN 10 204

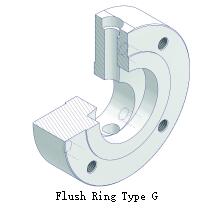

• Flush Ring Type G and Dual Flange Style Type D

– Concentric or excentric (flush ring type g only)

– 1 or 2 vent / fushing connections

– PFA lining optional (flush ring type g only)

– Adapting of nominal pipe size (NPS)

– Allows disassembly of diaphragm seal without removing the fush ring

Applications

• Flush rings are used for diaphragm seals in order to prevent clogging of the instrument connection.

• The fush ring is mounted between the process fange and the diaphragm seal.

0 comments:

Post a Comment