A welding joint is a point or edge where two or more pieces of metal or plastic are joined together. They are formed by welding two or more workpieces (metal or plastic) according to a particular geometry. Five types of joints referred to by the American Welding Society: butt, corner, edge, lap, and tee. These configurations may have various configurations at the joint where actual welding can occur.

There are four basic joints used in arc welding:

•Butt joints

•Tee joints

•Lap joints

•Corner joints

Each welding joint has several variations to provide for different needs. Two different types of welds are used when welding these joints. The groove-type weld (butt weld) fills in grooves that are cut on the inside of two pieces of metal that are positioned next to each other. The fillet-type weld fills in space on the outside of pieces of metal that are positioned at an angle to each other.

Butt welded joints

A Butt Weld is a circumferential butt welded joint, and the most common type of joint employed in the fabrication of welded pipe systems. A butt joint is the most universally used method of joining pipe to itself, fittings, flanges, Valves, and other equipment. This welding technique is widely applied in situations where a quality weld desired, and the weld by X-ray technically should be investigated.

When the material to be welded exceeds 3/16″ in thickness, the ends of pipes, fittings and flanges must be chamfered at approximately 37.5°, flared on a small upright side (Root face); in practice we talk about the Welding Bevel.

The most used bevels are the “Plain bevel” from wall thicknesses (t) 4 to 22.5 mm, and the “Compound bevel” for wall thicknesses above 22 mm.

ASME B16.25 covers the preparation of buttwelding ends of piping components to be joined into a piping system by welding. It includes requirements for welding bevels, for external and internal shaping of heavy-wall components, and for preparation of internal ends (including dimensions and dimensional tolerances). These weld edge preparation requirements are also incorporated into the ASME standards (e.g., B16.9, B16.5, B16.34).

During the prefab from a pipe on a elbow e.g., a “Gap” of approx. 3-4 mm should be created, to obtain a proper weld penetration.

The images below shows 3 examples

Fig.1 A correct preparation and right gap, creates a proper penetration.

Fig.2 A narrow gap, may be causes a hollow penetration.

Fig.3 A large gap, may be causes a too heavy penetration.

Fillet welded joints

Fillet welded joints such as tee, lap and corner joints are the most common connection in welded fabrication. In total they probably account for around 70 to 80% of all joints made by arc welding. No edge preparation is needed and assemblies in piping systems are simpler. Therefore, fillet welds are usually cheaper than butt welds.

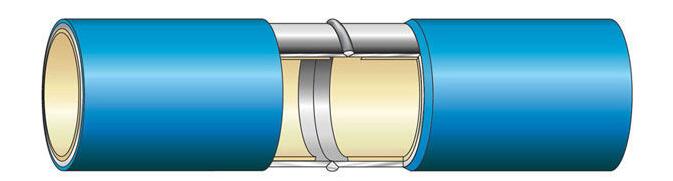

In pipe systems fillet welded joints are generally used for joining pipe to socket joints in sizes NPS 2 and smaller, and in systems where Slip On flanges will be used. The image below illustrates typical fillet welded joints in a Socket Weld pipe system.

ASME B31.1 1998 127.3 Preparation for Welding (E) Socket Weld Assembly says:

In assembly of the joint before welding, the pipe or tube shall be inserted into the socket to the maximum depth and then withdrawn approximately 1/16″ (1.6 mm) away from contact between the end of the pipe and the shoulder of the socket.

The purpose for the bottoming clearance in a Socket Weld is usually to reduce the residual stress at the root of the weld that could occur during solidification of the weld metal, and to allow for differential expansion of the mating elements.

The disadvantage of a Socket Weld system is right the expansion gap and the space between the OD of the pipe and the ID of the fitting. By corrosive products, and mainly in stainless steel pipe systems, the crack between pipe and flange, fitting or Valve can give corrosion problems.

I am not an expert in this matter, but on the internet, you will find a lot of information about forms of corrosion.

In service applications, where complete weld penetration to the inside of the piping is required, socket welds are not acceptable, and generally butt welds must be made.

0 comments:

Post a Comment