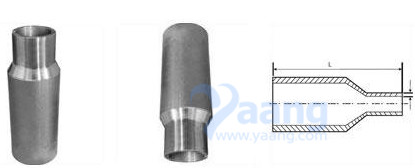

Swage nipples also named reducing nipple, one end large diameter one end small, they are made from forgings or formed by seamless pipes. The end of swage nipple is plain, beveled and threaded. The function of Swage nipples are the same as reducer the only difference is that they are generally used to connect butt welded pipe to a socket welded or screwed pipe.

There are also available as Concentric and Eccentric type.

|

|

The different end connections available are:

- PBE = Plain Both Ends

- BBE = Beveled Both Ends

- TBE = Treaded Both Ends

Size: 1/8″NB TO 4″NB IN

Schedule: SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS

Type: Seamless / ERW / Welded

Form: Pipe Nipple, Hex Nipple, Swage Nipple, Barrel Nipple

MATERIALS:

Stainless Steel Swage Nipple – SS Swage Nipple

ASTM A403 WP Gr. 304, 304H, 309, 310, 316, 316L, 317L, 321, 347, 904L

Carbon Steel Swage Nipple – CS Swage Nipple

ASTM A 234 WPB , WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70.

Low Temperature Carbon Steel Swage Nipple – LTCS Swage Nipple

ASTM A420 WPL3 / A420WPL6

Alloy Steel Swage Nipple – AS Swage Nipple

ASTM / ASME A/SA 234 Gr. WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 91

Duplex Steel Swage Nipple

ASTM A 815 UNS NO S 31803 , S 32205.

Nickel Alloy Swage Nipple:

Standard: ASTM / ASME SB 336.

UNS 10276 (HASTELLOY C 276 Nipple )

UNS 2200 (NICKEL 200 Nipple ),

UNS 2201 (NICKEL 201 Nipple ),

UNS 4400 (MONEL 400 Nipple ),

UNS 8020 (ALLOY 20 Nipple),

UNS 8825 INCONEL (825 Nipple ),

UNS 6600 (INCONEL 600 Nipple ),

UNS 6601 (INCONEL 601 Nipple),

UNS 6625 (INCONEL 625 Nipple )

Size range NPS 1/8 – NPS 8. Manufactured from seamless pipe or cold drawn bar which is heat treated in accordance with ASTM A234. Choice of raw material dependant upon size and reduction. Available wall thickness: standard (STD), extra strong (XS), schedule 160, or double extra strong (XXS).

0 comments:

Post a Comment