Welded pipe is made by forming flat products (strip, sheet or plate) into the desired shape, in this case, normally round. Once the desired shape has been achieved, a high energy source is used to melt the metal locally at the weld joint. It is squeezed together and allowed to solidify, forming a weld bead. The high energy source may be an electric arc, a plasma arc, a laser beam, or even an electron beam. The as-welded weld bead is typically somewhat thicker than the adjacent base metal and needs to be modified to match the base metal thickness, and to correct the undesirable physical, chemical and corrosion resistance attributes of the weld.

Welded pipe manufacturing

At the start of the welded pipe manufacturing process so called slabs or billets are cast in a steel mill. Dependent on the external dimensions and wall thickness there are different methods of producing welded pipes and pipes: Electric Resistance Welding (ERW), Fusion Welding (EFW) and Double Submerged Arc Welding (DSAW). In the ERW and EFW manufacturing process welded pipes are formed by hot or cold rolling plate and welding the seam. In order to keep the outside (O.D.) surface of a welded pipe smooth and uniform a cutting tool called scarfing blade is used to remove the weld flash. Scarfing from the inside (I.D.) welded flash is also possible. With a heat treating at the end of the manufacturing process the weld zone of the steel pipe can be made less visible. Due to the weld seam lower operating pressures are stated in accordance with ASME compared to seamless pipes. In general welded pipes possess tighter dimensional tolerances than seamless pipes and are less costly if produced in same quantities.

ERW pipe manufacturing

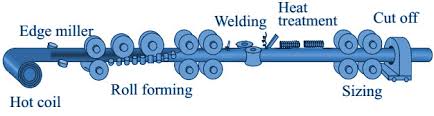

A process for producing welded pipes is Electric Resistance Welding (ERW) also known as Contact Welding. The manufacturing starts by cold-forming a coiled plate of steel with eligible thickness and certain width into a cylindrical shape. As the cylindrical plates come together, an electric current using heat merges the edges together to create the final product.

EFW pipe manufacturing

Processing of Electric Fusion Welding, also called Continuous Welding begins as coiled steel with appropriate thickness, width and weight is made. To form a continuous ribbon of steel several coils are welded together. Then the steel ribbon is heated to the necessary temperature and formed into an oval. In the next step the edges of the pipe strip are permanently pressed together by rolls in order to receive a forged weld. In the last stage sizing rolls convert the welded pipe into specific dimensions.

DSAW pipe manufacturing

The process of producing Double Submerged Arc Welded Pipes first contains forming steel plates into cylindrical shapes. Later on the edges of the rolled plate are forged so that v-shaped notches are on the exterior and interior area of the seam. Then the pipe seam is being welded by an arc welder submerged under flux.

Welded pipe sizes and dimensions

Welded pipes are used especially for pipeline constructions and for larger dimensions in the process plants; any specifications and qualities are part of our supply program.

For example, we supply carbon steel pipes for pipeline projects throughout the world according to:

API 5L X 52, X60, X65, X70

Welded carbon and alloyed process plant pipes in acc. to below standards:

ASTM A333, 671, 672, 691

Welded Stainless steel, special alloys pipes for chemical and petrochemical plants to:

ASTM A 312, 358, 778, 928, ASTM B 619, B725

All materials are also available in acc. to equivalent DIN/ EN standards and grades.

Some manufacturers will simply remove the excess material of the weld bead by scarfing the inside portion and either grinding or scarfing the outside portion. This method of weld bead modification only changes the physical dimension and leaves the undesirable as-welded physical, chemical and corrosion resistance properties as they were.

To properly modify this condition the weld bead is cold worked locally and is given a solution anneal heat treatment. This results in a microstructure that exhibits the same physical, chemical, mechanical, and corrosion resistance properties as the base metal.

The wall thickness advantage of comparison between welded pipe and seamless pipe

Welded pipe, being made from flat rolled strip material exhibits extremely consistent wall thickness. A 2.11mm nominal wall pipe typically shows actual variation of 0.07 mm or less at a point. The variation from production lot to production lot is typically 0.1 mm or less.

The dimensional flaw of welded pipe may be its ovality, or roundness. Seamless pipe has a very round and very consistent diameter as a result of being extruded through a die, with typical measured variations in diameter of +/- 0.025mm for a 25 mm OD size. Roll formed welded pipe on the other hand, typically varies about +/- 0.050 mm to +/- 0.075 mm for the same nominal OD. However, for most applications, good concentricity is more valuable than good ovality. Ovality can be corrected or compensated for during fabrication or installation. A non-concentric (or eccentric) condition cannot.

What are the criteria that should be considered?

Specifying a manufacturing process rather than specifying measurable results in any product is always a slippery slope. The type of results and the value of measureable results need to be performance-based and to consider application critical attributes. If working pressure is of concern, then a minimum tensile or yield strength or burst pressure value should be considered, along with dimensional attributes like wall thickness and concentricity.

Wall thickness and concentricity should also be of concern when heat transfer rates are an issue. pipes that exhibit a non-concentric or eccentric geometry may develop hot spots or weak spots at thin or thick sections around the circumference, as well as along the length. This could significantly affect process parameters in a heat exchanger.

If working temperature, either elevated or cryogenic, is of concern, test methods and data representative of the field conditions should be considered. Basically, if material selection is properly executed, the product form should be insignificant.

What is the advantage of seamless over welded?

When welded pipe is properly manufactured by a reputable supplier, seamless does not have any advantage over welded.

Which is more cost-effective? Why?

From a pipe manufacturing standpoint, typically welded is more cost-effective as a result of the minimised labour input and reduced manufacturing scrap.

From a fabrication standpoint, welded is more cost effective because of the reduced number of field orbital welds needed to join inpidual lengths of pipe together to create the umbilical.

Seamless pipes are typically available in fixed finite lengths such as 6 or 12 metres. Welded pipe on the other hand is available in continuous lengths up to 25,000 metres. A single continuous pipe from a coil of strip material is typically about 500 metres long. A splice weld is made on the strip material at these 500 metre intervals and is cold worked before roll forming the pipe. It is then solution anneal heat treated and X-ray examined. The net result is that strip material is infinitely long and the final length of the pipe is then limited only by the size of the spool on which it can be coiled and the associated material shipping and handling capabilities.

Because these splice (orbital) welds are made and processed at the factory in a controlled environment the potential for corrosion is significantly reduced as compared to the field orbital welds which cannot be cold worked and are typically not heat treated. The microstructure and the physical, chemical and corrosion resistance properties of the factory welds are virtually identical to those of the base metal.

When purchased from a reputable reliable supplier, welded pipe can offer advantages of economy without sacrifice of performance. The economy is realised in both initial purchase costs and in time and labour in fabrication / installation. Coiled welded pipe can be supplied with a splice (orbital) weld that has been cold worked and solution annealed at intervals of about 500 metres. The maximum distance between splice welds in coiled seamless pipes is typically about 30 metres. The wall thickness dimension control of welded pipe is superior to that of seamless pipe.

Welded pipe is acceptable as per most pressure vessel codes, and with additional non-destructive examination it can be used in place of seamless for lethal service applications.

With the rapid development of high-quality strip rolling production and progress of welding and testing technology, and constantly improve the weld quality, varieties and specifications of stainless steel welded pipe is increasing, and in more and more fields especially in the heat exchanger pipe, oil pipeline and other aspects instead of the seamless steel pipe.

0 comments:

Post a Comment